Modular construction

In recent years, modular construction, especially CLT wood construction, has become increasingly popular. This is not surprising given the need for housing and the explosion in the price of building materials. Modular construction has many advantages over traditional construction. We present here this new mode of construction that is ecoresponsible, flexible, affordable and sustainable. You can choose between basic modules or fully customize them yourself. They can be tiny houses, modular houses, modular offices or mobile and/or fixed modular buildings.

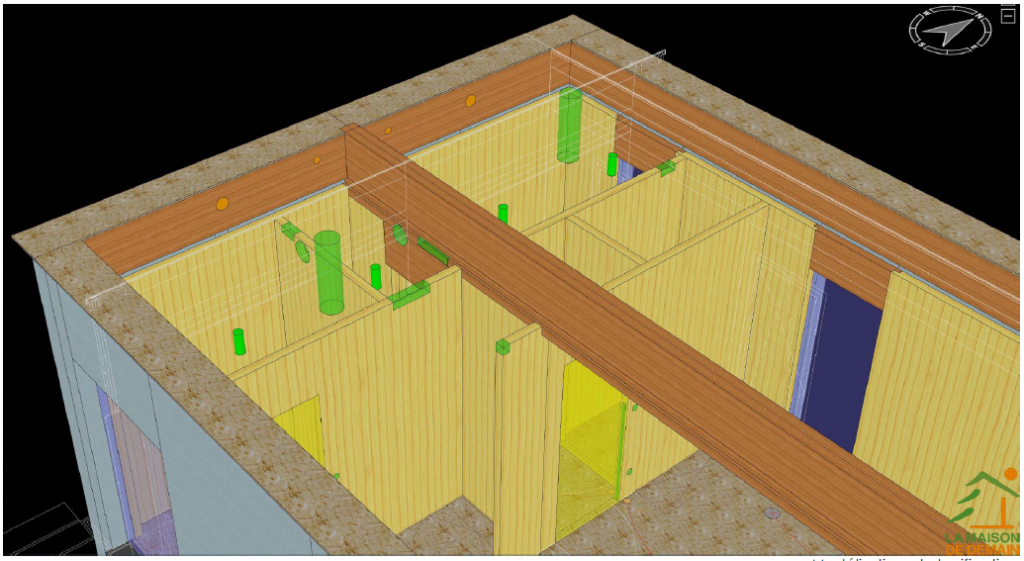

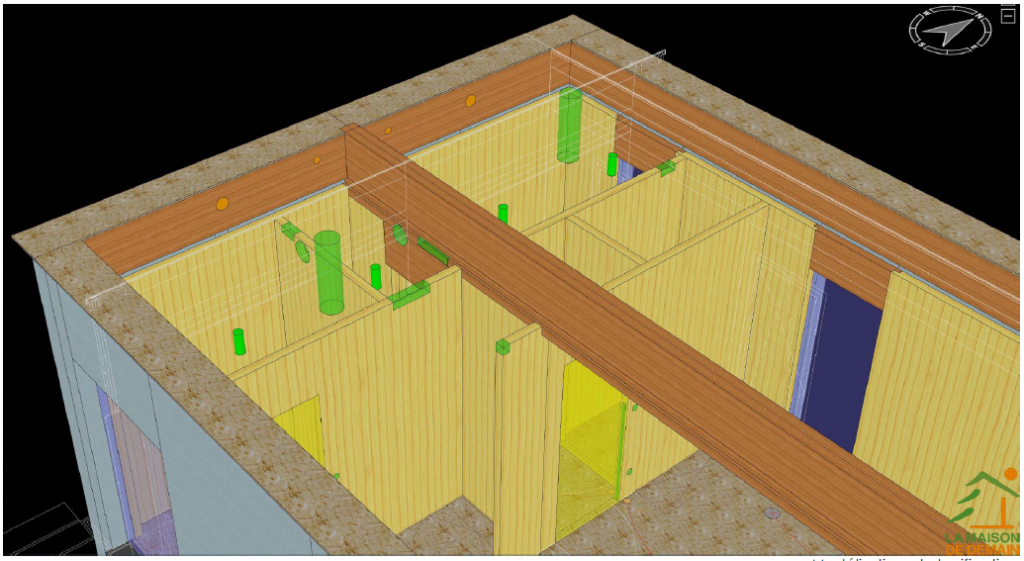

The principle is relatively simple: modular construction consists of factory pre-assembled modules that are 100% ready to use. They are equipped in advance with electrical and sanitary installations. The interior finishing touches are even planned at this stage. The modules are then transported by truck and assembled on your site. In this context, the modular wood construction CLT is particularly popular, because it is a lighter and environmentally friendly material than other traditional building materials. Off-site construction allows us to think about all aspects upstream and avoid problems on the construction site.

This versatile construction technique allows projects of different sizes to be built by installing modules side by side or on top of each other. They can be used in a fixed or mobile way. In fact, they can be dismantled and reassembled elsewhere. Much more than a simple container or caravan, it is a fully equipped space, design, comfortable and pleasant for the occupants or users.

The prefabrication of the modules streamlines the construction process and the site. In addition, there is no need to dig a foundation, which also reduces costs and time. We can therefore offer you a more interesting price per m² than traditional constructions.

The energy performance of CLT modular wood construction elements is exceptional. Energy standards are often similar to those of passive (low energy) buildings . The naturalthermal insulation of wood will allow you to limit your energy consumption (heating and cooling).

All elements are pre-assembled in our workshop. We have all the necessary materials and equipment. We do not experience the same delays as traditional construction, especially due to bad weather conditions. So you can enjoy your new space in just a few months. We estimate that the construction time is reduced by 40 to 60% (including prefabrication + assembly).

The assembly of the pre-assembled CLT elements on site is very fast. Halzebatz modules are assembled and equipped within a few days. The use of wood allows for a dry construction method, as opposed to the traditional construction method (“wet”, like cement). Therefore, no drying time is required and finishing can be done immediately. This means you can enjoy it faster.

The modular and flexible construction offers a great deal of freedom of choice in terms of size and layout. We understand that your needs are different for a home, an office, or a visitor’s building. We are therefore at your disposal to determine together the best configuration for your project.

Given the possibility of recycling, their lowCO2 footprint, the materials used, the limitation of necessary transport, but also their exceptional energy efficiency , our CLT wood modules are an environmentally responsible choice. The use of high quality materials will allow several generations to enjoy it.

Our modules can be disassembled and reassembled elsewhere, which promotes mobility and therefore thecircular economy. No need to demolish. Moreover, our modules do not require foundations: they are simply placed on screwed piles (6 per module). The site can therefore easily be returned to its original state after dismantling.

Off-site construction allows for better working conditions. We can better guarantee safety and our employees are more productive. The transport of materials and workers is also greatly reduced. Pre-assembly also limits noise, waste and environmental disturbance on your property. Your site also stays cleaner.

CLT stands for Cross Laminated Timber. It comes in the form of multi-layer wood panels. The layers are crossed at 90 degrees and glued, which gives them excellent rigidity and stability. The structural elements of the modules are cut out of these CLT wood panels.

This method has many advantages over wood framing that relies on solid laminated wood panels.

CLT | Wooden frame |

No beams, but a solid wood structure with uninterrupted exterior insulation: | Alternating wooden beams and flexible insulation between these beams: |

No need for a general vapour barrier: | General vapour barrier required. |

CLT can be used for interior finishing. | Interior finishes must be provided. |

Our CLT wood comes from the Grande Région, an area covering part of Luxembourg, Germany, Belgium and France. Our modules are also manufactured in this region. Our solutions are therefore 100% made in Europe.

NB: a technical preparation of your land must be foreseen beforehand (unevenness, slope, electricity, water…). As an option, we will accompany and advise you in this regard.

Here are some examples of how Halzebatz CLT wood modules can be used: